703 666 8193

Phone number

orders@patchvilla.com

Email address

Phone number

Email address

Patches have emerged as one of the loudest ways of self-expression, sewn onto clothes, bags, hats and more to share personality and style with the world. Sublimated patches because of their vibrant design, durability and versatility, have been gaining popularity in the ever-evolving world of custom patches. Here at Patch Villa, we welcome this trend by offering a wide range of high-quality custom patches for your creative needs.

Sublimated patches are also named dye-sublimation patches, which are customized patches made by a special printing process using sublimation. This technique involves printing a design onto a transfer paper using sublimation ink, which is then transferred onto a patch fabric through heating and pressure. The heat turns the ink into gas and it then bonds with the fibers of the fabric, producing a bright and long-lasting image.

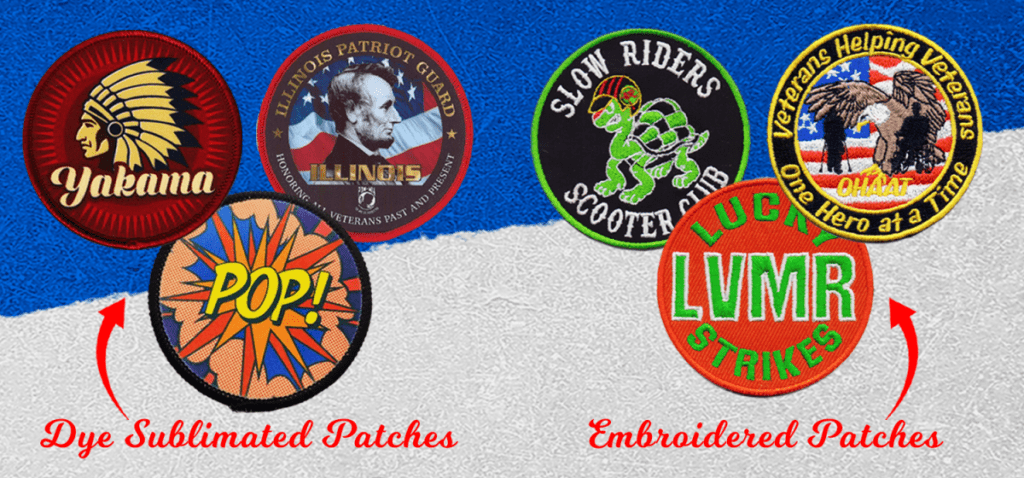

Unlike the traditional embroidered ones, which create a design using threads, sublimated patches allow one to get more detailed and colorful designs, like gradients, complex logos and even photographic images. The result is a sleek, smooth surface with unlimited design possibilities.

Sublimated patches are basically available in several styles that can suit a wide array of needs. From fashion statements, team badges to accessorizing, here are some common types of sublimated patches that one can choose from.

These patches have a fully sublimated design that means the whole surface of the patch is printed by the sublimation process. Full sublimation patches are ideal for detailed designs, logos and graphics that demand complex colors with extreme details.

Best Uses:

If you like the traditional look and feel of embroidery but would like the bright details of sublimation, combo patches are for you. A combo patch is a beautiful combination of both since it features an embroidered border or accent with a sublimated design in the middle. This provides texture and high-definition graphics.

Best Uses:

Sublimated applique patches modernize the traditional style of applique. A design is sublimation printed onto a fabric background, felt or twill works well and then is cut into desired shape. These work very well for larger designs to be more noticeable.

Best Uses:

Die-cut patches are those kinds of sublimated patches that are in custom shape and do not follow the traditional round or square cuts but are cut into unique shapes to complement a design. These patches are great for adding unique flair to any garment or accessory.

Best Uses:

Are you ready to enter the DIY world and make some sublimated patches from your home? Even though professional sublimation equipment is rather costly, you are able to create sublimated patches if you use just a few uncomplicated tools and materials that are accessible with much ease. Here is how you can get started:

Materials You’ll Be Needing:

Sublimation Printer: You shall require a printer capable of working with sublimation ink. For this process, ordinary inkjet printers just won’t work.

Sublimation Ink: The process requires special sublimation ink.

Sublimation Transfer Paper: This holds the design of the sublimation ink before its actual transfer onto the fabric.

Heat Press: Ink is transferred from paper to fabric by the use of high heat and pressure via a heat press.

Blank Patches or Patch Fabric: You need to procure blank polyester patches or fabric that will contain high polyester content, at least 65% polyester, for better performance.

Scissors or Die-Cutting Machine: You would need sharp scissors to cut your patches into custom shapes, alternatively use a die-cutting machine for precision.

Design Your Patch

First of all, you have to create or choose a design. You can use the facility of any design software like Adobe Illustrator or Canva to create a high-resolution image. Make sure your design fits within the dimensions of your patch. You could create several designs on one sheet of sublimation transfer paper.

Print the Design

Using a sublimation printer, print your design onto sublimation transfer paper. Be sure to reverse or mirror the image so that it appears correctly when transferred to the patch fabric. The colors will appear somewhat dull on the paper, but be not alarmed. Once the image is transferred, they are bright.

Prepare the Blank Patch or Fabric

Place them in your heat press if working with blank patches. If using patch fabric, you will need to cut the fabric into your desired patch shape prior to sublimation. For sublimation, polyester fabric works the best because the dye directly bonds with the synthetic fibers.

Transfer the Design

Place the sublimation transfer paper face down onto the blank patch or fabric. Set your heat press at the recommended temperature setting, which is approximately 400°F or 200°C for about 30 to 60 seconds under even pressure. The resulting heat will sublimate the ink into vapor to attach itself to fibers within the fabric.

Cool and Peel

When the timer of the heat press goes off, carefully lift the press and let the patch cool for a few moments. Then peel off the sublimation paper to reveal your newly sublimated patch.

Finishing Your Patch

Cut your design into the preferred shape, using either scissors or a die-cut machine, if you apply patch fabric. Add an iron-on backing to make it last, sew the patch onto your item or apply adhesive backing where applicable.

Pro Tip:

To give it that little extra oomph, consider embroidering an outline around your sublimated design for added texture and that professional finish in your DIY patch.

Sublimation requires the right materials to come up with the best results. Listed here are the commonly used materials in sublimated patches:

Polyester Fabric

Sublimation works best with polyester or poly-blend fabrics because in the process of heat transfer, the ink bonds to the synthetic fibers. The higher the polyester content in a fabric, the more striking and resilient the sublimation print. There are plenty of smooth and flexible polyester patches, hence generally used for very detailed designs.

Twill Fabric

Twill is the strong, textured fabric which has been standard for embroidered patches. Sublimated twill patches are the perfect combination of durability of the twill and design flexibility of sublimation. Twill has a fairly textured background that could add an extra bit to the appearance of the sublimated design.

Felt Fabric

Felt patches come with a softer, textured look and give a more hand-crafted look and feel to sublimated patches. While felt is less smooth than polyester, it can be used for sublimation when properly prepared. Felt patches are perfect for applique style patches.

Heat Transfer Vinyl (HTV)

Sublimation can also be done on heat transfer vinyl, which provides a rather metallic or glossy appearance. These are usually utilized in making sublimated patches, which come with an almost reflective, very shiny finish that is quite perfect for fashion-forward designs.

The versatility of sublimated patches opens the door to endless creative uses. A few uses could be:

Fashion and Apparel

Sublimation patches have been excellent for jackets, jeans, t-shirts, and even caps. For updating an old denim jacket or adding that little something to a new piece of garment, a patch is going to be a good addition.

Sports and Team Patches

From sports teams to school clubs, sublimated patches can showcase team logos and mascots with accuracy. Their bright colors and intricate designs create the perfect look for uniforms and spirit wear.

Event Keepsakes

Commemorate special events such as festivals, weddings, or corporate affairs using custom-made sublimated patches. These patches can be given out as keepsakes or stitched onto event merchandise.

Business Branding

Sublimated patches have become an affordable tool for brand promotion. Put your company logo on hats, bags, or uniforms for consistent and professional branding.

Craft Projects

Sublimation patches are ideal to go for any DIY craft project. Apply to personalize one’s backpack, home decor things, or even scrapbooks.

At Patch Villa, we present you with the opportunity to create the most high-quality imagined sublimated patches. Be it a bulk order for your business or a special design for yourself, our custom patches are stitched together with perfection. We use top-notch materials and advanced methods of sublimation in making your patches bright, tough, and durable.

With Patch Villa, you can choose a style, material and design. From the do-it-yourself hankering homemaker to the professionally made patch expert, we have got you covered.

Let your creativity loose and start making your sublimated patches today. Check out Patch Villa for all your custom patch options and let your imagination run wild.